Top Rated Metal CNC Machine Shops Reviews and Ratings

People also used these services

See the 2015 Top Rated CNC Machine Shops on VendOp

About CNC Machining

CNC Machining, which stands for Computer Numerical Control Machining was first introduced in the 70's. It is a subtractive manufacturing process where material is removed to create the final part. As the power of the computer has increased, so has the capabilities and prevalence of CNC manufacturing process. The machining process is completely controlled by computers allowing for quick, accurate, reproducible and amazing parts to be made.

So how does this work? First off, you need to design the part using a CAD or CAM program. There are many out there and some of the more popular ones are, AutoCAD, SolidWorks, Pro-E, Autodesk and new player, Onshape. The design is very important. Remember, the CNC machine has to be able to reach the area in order to remove materials. It is easy to design a part that cannot be made using using this process, so keep this in mind as you are creating the part. With the modern machines, more creative methods are being used to make parts and devices that would not have been possible a few years ago.

Now you have the part and ready to have it made. All the hard work is done, now just let the computer bring your creation to life. Right? Not quite. CNC Machining is a generic term for any computer controlled manufacturing equipment. In fact, you can have a CNC Mills, Lathes, Wire EDM, Plasma Cutters and may other machines. Knowing which type of machine to use on your part can be key to not only having the best final product, but also to keep down cost and time necessary to create the part. Skilled machinist are still a key player when looking for a CNC shop. While the computer now replaces some of the manufacturing skill, the machinist will still make a huge difference in the outcome of the final product. Here is a great set of articles that explains work and effort that goes into setting up and running a CNC machine.

Design Considerations:

Like most manufacturing processes, the design and material selected greatly affects the cost and functionality of the final product.

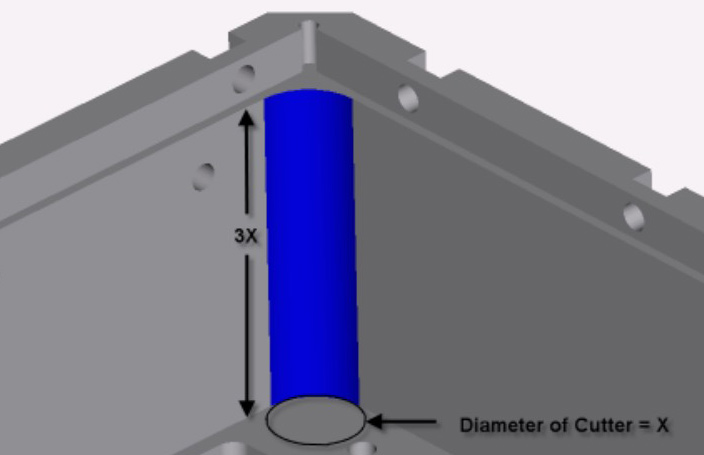

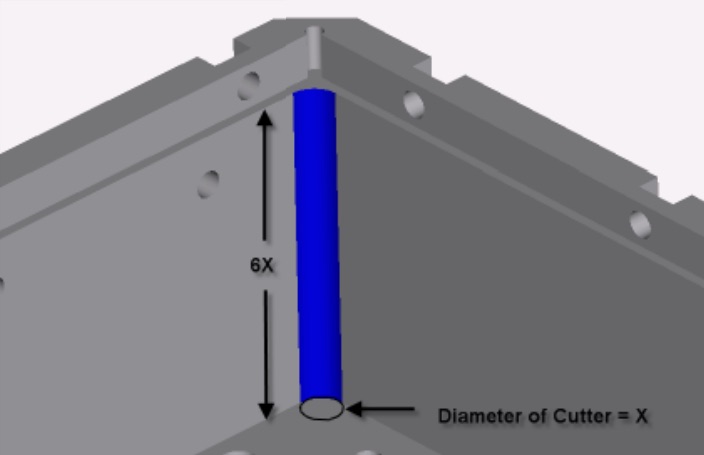

Features in the design - The tool for most types of CNC Machines must be able to reach the areas where material needs to be removed. One example is the design of interior corners. Interior corners should have a radius. The depth of the part determines how small of an interior radius that can be machined. The tool must be rigid enough to be able to cut through the metal, plastic or other material with out flexing. This is accomplished by having a larger diameter for the longer cutting tools. Pro CNC has a few resources that help explain some of the caveats to keep in mind when designing the part.

Material Selection - Tools can cut through plastics easier than metals. This must make it easier to machine plastics. Wrong, in fact, ductile materials are more difficult to machine than most brittle materials. One of the key factors to machinability is the hardness of the material. A plastic is ductile, it may flex during machining and deform. In addition, depending on the melting temperature of the plastic, it can melt if the machining speed it too high. Both plastics and metals of different materials that are easier to machine than others. The properties of the material have a dramatic affect on the cost of machining, speed at which the material can be removed and the resulting surface finish.

Tolerances - This is one of the many factors in the cost and time to manufacture a part on a CNC machine. When designing the part, good general practice is to specify the loosest tolerance that will still allow the part to function. Individual features should tolerances specified. If only one feature requires a tight tolerance, do not apply that features tolerance to the entire part. In addition, certain types of features and materials are much easier to maintain a tight tolerance. This is where a good machinist is one of your most valuable assets. They can help with making small modifications to the part which can save a lot of money.

CNC Machining vs. Manual Machining

This is probably one of the more controversial topics and "pure" machinist will continue to advocate the advantages of manual machining. A search on the topic on the web brings up a few eye-catching results. "CNC machining vs. Craftsmanship", "What is a manual machinist" both of these topics demonstrate the strangle hold that CNC has over manufacturing. Someone even made a Legos CNC milling machine.

Manual machining is quickly being limited to creating low volume prototypes and for small shops that do not have the capital to buy a more expensive CNC machine.

| CNC | Manual | |||

|---|---|---|---|---|

| Hours of Operation | Can operate 24/7 | Requires attendance by operator | ||

| High volume parts | Automated to make the same part over and over | Requires each part to be manually made | ||

| Upgrades | Software upgrades can improve performance | Dependent on increasing the skills of operator | ||

| Accuracy | 99.9% accurate to the design | Human errors can cause defects | ||

| Labor Cost | One operator can oversee many machines | Each machine requires an operator | ||

| Equipment Cost | Expensive to purchase | Cheaper and easy to find used | ||

| Per part cost | High volume parts much cheaper | A single part might be cheaper |

Types of CNC Machining

As mentioned before, most types of machining can be CNC controlled. Even among the same type of machine, there are different capabilities. The two main types of CNC machines are 3-axis and 5-axis. What is the difference?

A 3-axis CNC can control 3 different axis of motion. Makes sense right? These are x-axis, y-axis and z-axis. A 5-axis machine allows for two more axis of motion. The two axes are ability to tilt and rotate the part or tool head. What are the benefits of a 5-axis machine over a 3 axis? Basically it is the same as CNC machining over manual machining, speed, accuracy and part cost.

Example of 3-axis machining

Example of 5-axis machining

Find the best CNC machine shop by reading reviews written by previous customers

What you should know about finding the right company for your business

See the trending Metal CNC Machining companies with reviews

| # | Company | Reviews | Rating |

|---|---|---|---|

| 1 | ABC Sheet Metal | 3 | |

| 2 | Accellent Inc - (Now Lake Region Medical) | 47 | |

| 3 | Accurate Manufacturing Co | 30 | |

| 4 | Apex Machining | 3 | |

| 5 | Ayala Research Corp | 5 | |

| 6 | Bob's Machining Co | 3 | |

| 7 | C-Axis | 3 | |

| 8 | CMC Engineering | 2 | |

| 9 | Centerline Precision | 5 | |

| 10 | Doerksen Precision Products | 25 | |

| 11 | Hill Manufacturing | 8 | |

| 12 | Hoosier | 26 | |

| 13 | Hub Associates | 33 | |

| 14 | Kalman Machining Inc | 8 | |

| 15 | Precision Mold Technologies | 6 | |

| 16 | Seastrom Manufacturing Co Inc | 8 | |

| 17 | Small Precision Tools - SPT | 21 | |

| 18 | Tecomet Inc | 5 | |

| 19 | United Metal Spinning & Machining | 5 | |

| 20 | Wightman Engineering Svc | 3 |